Digital printing is used in location of screens to prevent lots of water waste, the business said, and several of the business’s fabrics are not dyed at all. rather, the business depends on an upcycling process by separating recycled fibers mechanically by color.

The business’s attention to its environmental effect likewise reaches its supply chain. “Most of our materials are knit near where our garments are made. That is definitely reducing our carbon footprint,” states Chou. “I put an emphasis on having factories in America … our denim is manufactured in America and in the future we’re taking a look at tee shirts and sports to be manufactured in America.”

“I started developing Everybody & & Everyone from the ground-up, very first by getting the very best team in location then by finding the ideal suppliers, producers and partners who were already making strides in the sustainability area,” Chou said in a statement. “I wanted this brand to be for every single woman, so body inclusivity, positivity and sustainability were going to be the foundation of whatever we did. We then built the brand names sustainable & & technical pillars, which include activation, recycled, dyeing & & printing, naturals done better, bio-based fibers and end usage to ensure our items would lessen unfavorable effects. We are sustainable down to the labels sewn into each garment.”

Some clothes are likewise made with materials that have actually recycled silver in them– so that the clothes can be used several times without smelling or the requirement for a wash.

Because that revelation, Chou dove into the world of sustainable manufacturing head-first. Through her family’s financial investment lorries she has actually dealt with companies like Modern Meadow, which utilizes bio-engineering to make leather products in a laboratory. Chou has actually likewise led financial investments in Thousand Fell, a soon-to-launch maker of completely recyclable shoes; Dirty Labs, which is developing more sustainable laundry cleaning products; and Carbon Engineering, which is establishing a direct air capture innovation for co2.

“For our brand name, recycled is a huge story for us,” says Chou. “Our tee shirts, our socks, our product packaging, our mailers, our labels, our stickers are all made from recycled materials that can be recycled again.”

For Chou, an understanding of the ecological toll that the family organisation was handling the planet began 6 years earlier– a couple of years before Iconix Brand Group got the China subsidiary she had actually co-founded with her daddy in a deal reportedly worth $56 million.

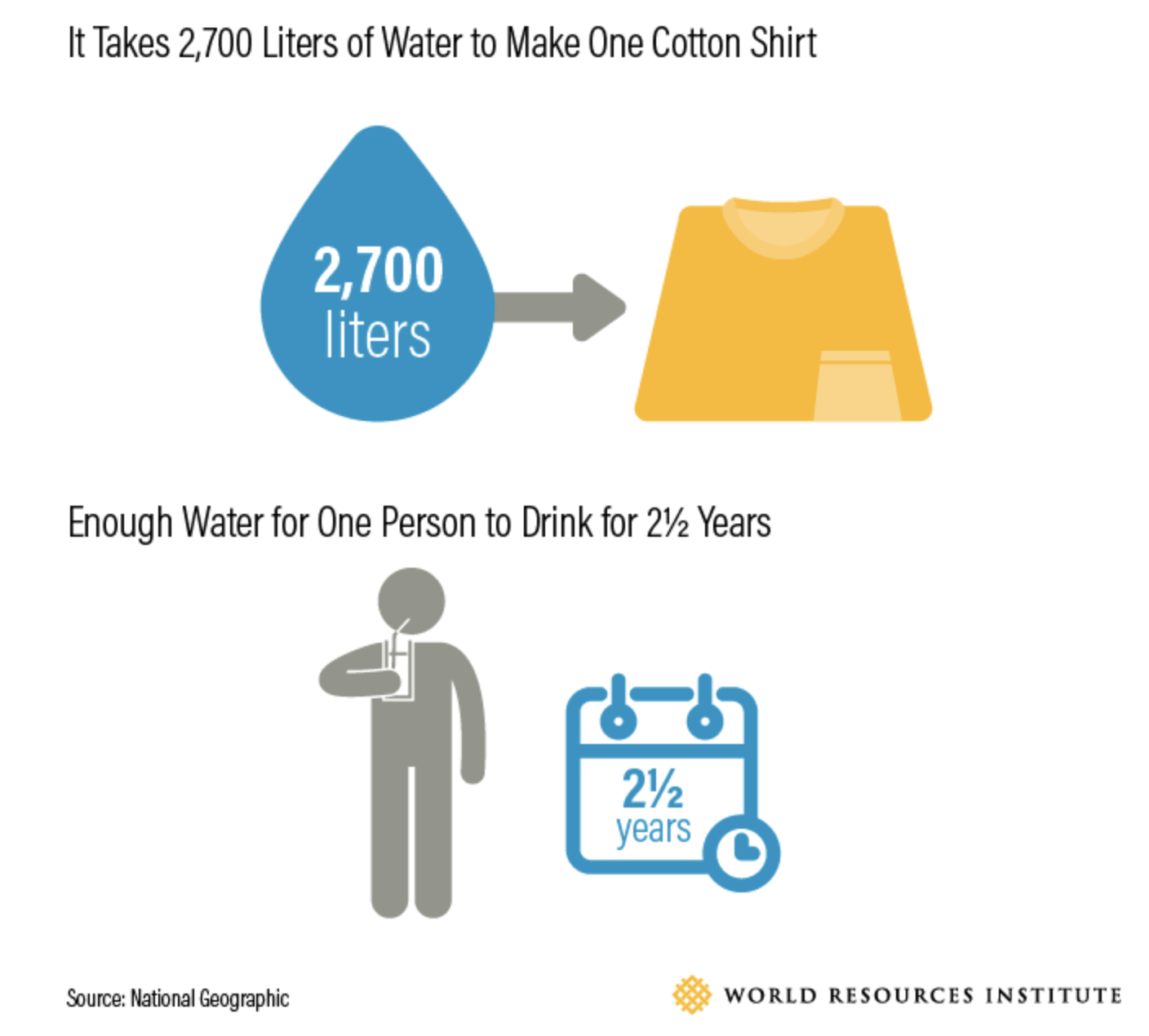

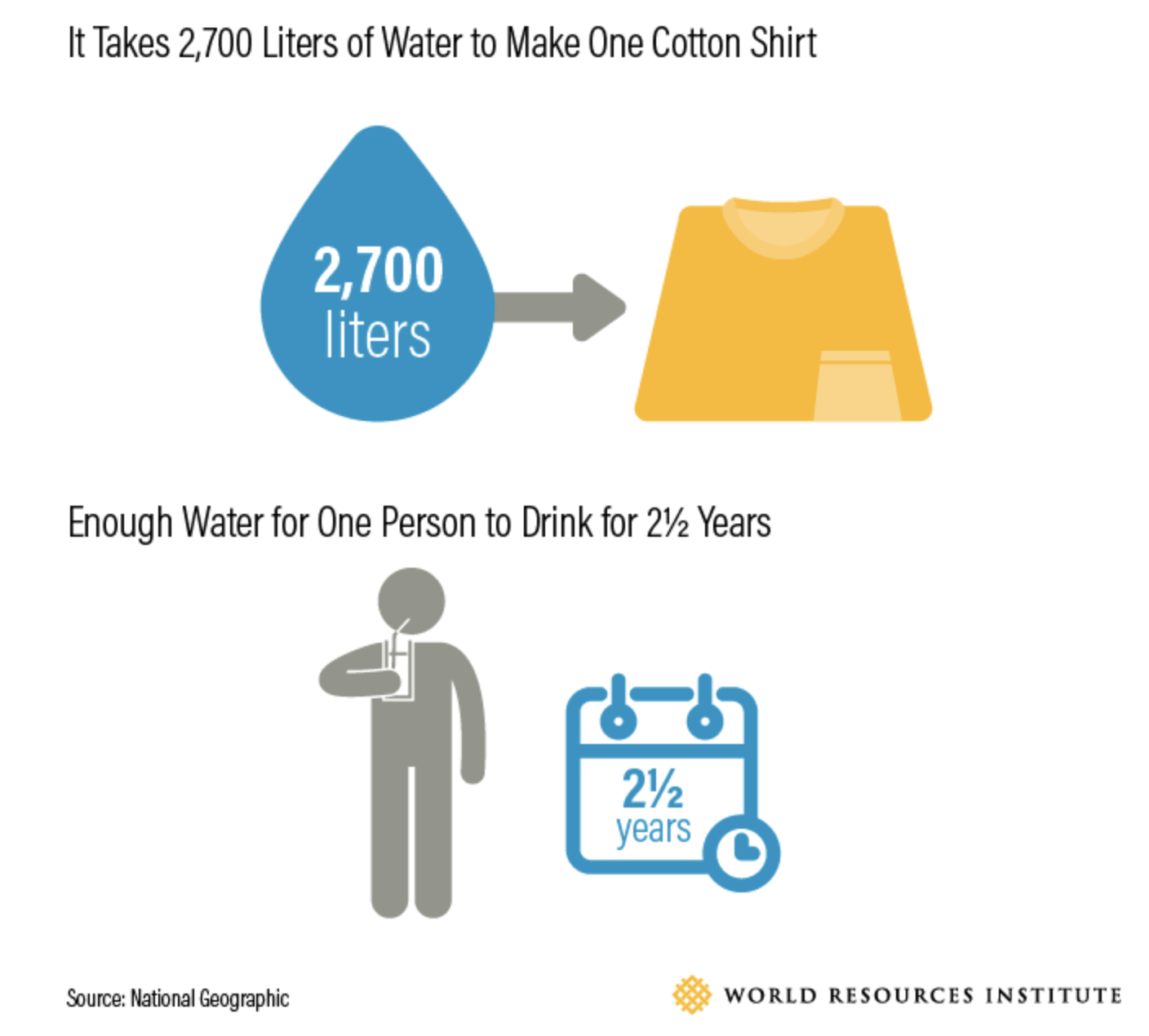

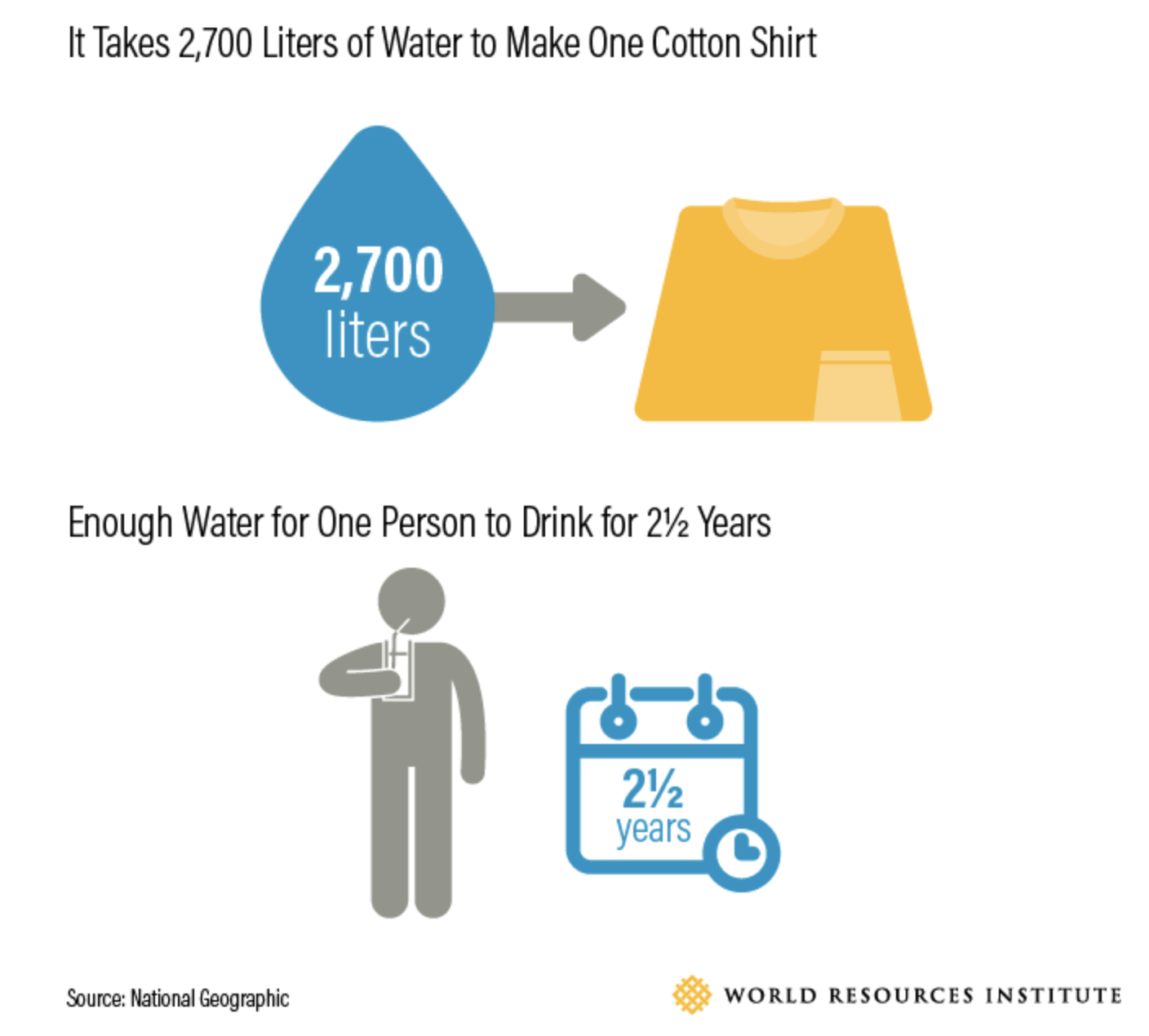

Image thanks to World Resources Institute

Everybody & & Everyone applies the lessons that Chou has actually discovered sustainability to a new style brand name that she hopes can serve as a model for how to weave sustainability into every element of the industry.

The new brand name, which sells females’s clothing for every size from 00 to 24 and at costs varying from $18 to $288 (most fall in the $50 to $150 variety, offered a quick scroll through the business’s new site) partners with business like Naadam and Ecoalf for sustainable cashmere and recycled materials made from plastic.

It was around the time that Chou had her kids, she says, that she understood the value of making a brand name that was both ecologically sustainable and inclusive.

Everyone & & Everyone has also partnered with the company One Tree Planted to plant a tree for each purchase that’s made with the company. In addition, the business has actually determined its carbon footprint from all of its pre-launch activities and has purchased and retired offsets to balance its emissions, Chou says.

As the fashion industry has actually expanded, so has the wealth of the Chou family. South Ocean Knitters, the knitwear producer started by Chou’s grandfather, was accountable for one of the very first foreign financial investments into mainland China in 1974. It is now among the largest providers of knitwear on the planet, and, together with the Hong Kong maker Li & & Fung, lags the Cobalt Fashion Holding conglomerate.

of the fashion business on the environment. The textiles market mainly uses non-renewable

resources– on the order of 98 million tons per year. That includes the oil to make synthetic fibers, fertilizers to grow cotton and poisonous chemicals to dye, treat and produce the fabrics utilized to make clothing. The greenhouse gas footprint from textiles production was roughly 1.2 billion lots of CO2 equivalent in 2015– more than all global flights and maritime shipments integrated(and a lot of those maritime shipments and worldwide flights were transporting clothes). The list of catastrophes that can be credited to the clothes market reaches contamination, as

“It was six years ago I began discovering about sustainability and five years ago that I said that I needed to have a sustainable brand,” says Chou.

well. About 20 %of industrial water pollution worldwide can be traced to the dyeing and treatment of fabrics– and microplastics from polyester, acrylic and nylon are contaminating the world’s oceans. Meanwhile, the increase of fast style has motivated consumers to accelerate waste. Approximately one trash truck loaded with clothes is landfilled all over the world every 2nd, according to a 2017 report from the Ellen MacArthur Foundation. That implies customers are discarding around $400 billion worth of important items every year as low prices and more “seasons” create an illusion of disposability.

Veronica Chou’s household has actually made its fortune at the forefront of the quick fashion industry through investments in companies like Michael Kors and Tommy Hilfiger. However now, the heiress toan estimated $2.1 billion fortune is releasing her own company, Everybody & Everyone, to show that the fashion business can be both environmentally sustainable and profitable. There’s no argument about the unfavorable effects

And her father, Silas Chou, made millions as a financier in Michael Kors and Tommy Hilfiger. As an executive at Iconix Brand Group China, Veronica Chou played a function in the acceleration of the industry– bringing American brand names to Chinese customers. Chou likewise functioned as the co-founder of the Beijing-based private equity fund China Consumer Capital and as a director of Karl Lagerfeld Greater China.

Veronica Chou’s family has made household fortune at the forefront of the fast fashion business through investments in companies financial investments Michael Kors and Tommy Hilfiger. And her dad, Silas Chou, made millions as a financier in Michael Kors and Tommy Hilfiger. As an executive at Iconix Brand Group China, Veronica Chou played a function in the acceleration of the industry– bringing American brand names to Chinese consumers. Since that revelation, Chou dove into the world of sustainable manufacturing head-first.”For our brand name, recycled is a huge story for us,” says Chou.

Veronica Chou’s family has made household fortune at the forefront of the fast fashion business through investments in companies financial investments Michael Kors and Tommy Hilfiger. And her daddy, Silas Chou, made millions as an investor in Michael Kors and Tommy Hilfiger. As an executive at Iconix Brand Group China, Veronica Chou played a function in the velocity of the market– bringing American brands to Chinese consumers.

Veronica Chou’s family has made household fortune at the forefront of the leading edge fashion business through investments in companies financial investments Michael Kors and Tommy Hilfiger. And her daddy, Silas Chou, made millions as a financier in Michael Kors and Tommy Hilfiger. As an executive at Iconix Brand Group China, Veronica Chou played a function in the acceleration of the market– bringing American brands to Chinese consumers. Since that discovery, Chou dove into the world of sustainable production head-first.”For our brand name, recycled is a big story for us,” says Chou.

Veronica Chou’s family has made household has actually at the forefront of the fast fashion business through investments in companies like Michael Kors and Tommy Hilfiger. And her daddy, Silas Chou, made millions as a financier in Michael Kors and Tommy Hilfiger. As an executive at Iconix Brand Group China, Veronica Chou played a function in the velocity of the market– bringing American brands to Chinese customers. Since that revelation, Chou dove into the world of sustainable production head-first.”For our brand, recycled is a big story for us,” states Chou.

Veronica Chou’s family has made household has actually at the forefront of the leading edge fashion business through investments in companies like Michael Kors and Tommy Hilfiger. And her father, Silas Chou, made millions as a financier in Michael Kors and Tommy Hilfiger. As an executive at Iconix Brand Group China, Veronica Chou played a role in the velocity of the market– bringing American brand names to Chinese customers.

Veronica Chou’s family has made its fortune at the forefront of the leading edge fashion business through investments in companies like Michael Kors and Tommy Hilfiger. And her father, Silas Chou, made millions as an investor in Michael Kors and Tommy Hilfiger. As an executive at Iconix Brand Group China, Veronica Chou played a role in the velocity of the industry– bringing American brands to Chinese customers.

Veronica Chou’s family has made household has actually at the forefront of the fast fashion business through investments in companies like Michael Kors and Tommy Hilfiger. And her father, Silas Chou, made millions as an investor in Michael Kors and Tommy Hilfiger. As an executive at Iconix Brand Group China, Veronica Chou played a role in the acceleration of the market– bringing American brands to Chinese consumers. Because that discovery, Chou dove into the world of sustainable production head-first.”For our brand, recycled is a big story for us,” says Chou.

Veronica Chou’s family has made household fortune at the forefront of the fast fashion business through investments in companies like Michael Kors and Tommy Hilfiger. And her dad, Silas Chou, made millions as a financier in Michael Kors and Tommy Hilfiger. As an executive at Iconix Brand Group China, Veronica Chou played a function in the acceleration of the market– bringing American brand names to Chinese consumers.

Veronica Chou’s family has made household has actually at the forefront of the leading edge fashion business through investments in companies financial investments Michael Kors and Tommy Hilfiger. And her dad, Silas Chou, made millions as a financier in Michael Kors and Tommy Hilfiger. As an executive at Iconix Brand Group China, Veronica Chou played a function in the velocity of the market– bringing American brands to Chinese consumers. Because that discovery, Chou dove into the world of sustainable manufacturing head-first.”For our brand, recycled is a huge story for us,” states Chou.

Veronica Chou’s family has made household fortune at the forefront of the leading edge fashion business through investments in companies financial investments Michael Kors and Tommy Hilfiger. And her dad, Silas Chou, made millions as an investor in Michael Kors and Tommy Hilfiger. As an executive at Iconix Brand Group China, Veronica Chou played a role in the acceleration of the market– bringing American brands to Chinese consumers. Because that discovery, Chou dove into the world of sustainable production head-first.”For our brand name, recycled is a huge story for us,” states Chou.

Veronica Chou’s family has made household fortune at the forefront of the leading edge fashion business through investments in companies financial investments Michael Kors and Tommy Hilfiger. And her dad, Silas Chou, made millions as an investor in Michael Kors and Tommy Hilfiger. As an executive at Iconix Brand Group China, Veronica Chou played a role in the velocity of the industry– bringing American brands to Chinese consumers.

Digital printing is used in location of screens to prevent lots of water waste, the business said, and several of the company’s fabrics are not dyed at all. rather, the company relies on an upcycling process by separating recycled fibers mechanically by color.

The company’s attention to its ecological effect also encompasses its supply chain. “Most of our materials are knit near to where our garments are made. That is certainly minimizing our carbon footprint,” says Chou. “I put an emphasis on having factories in America … our denim is manufactured in America and in the future we’re looking at athletics and t-shirts to be manufactured in America.”

As the style organisation has actually broadened, so has the wealth of the Chou family. South Ocean Knitters, the knitwear producer begun by Chou’s grandpa, was accountable for among the first foreign investments into mainland China in 1974. It is now one of the biggest suppliers of knitwear on the planet, and, together with the Hong Kong maker Li & & Fung, is behind the Cobalt Fashion Holding conglomerate.

Image thanks to World Resources Institute

And her father, Silas Chou, made millions as a financier in Michael Kors and Tommy Hilfiger. As an executive at Iconix Brand Group China, Veronica Chou contributed in the acceleration of the industry– bringing American brands to Chinese consumers. Chou also acted as the co-founder of the Beijing-based personal equity fund China Consumer Capital and as a director of Karl Lagerfeld Greater China.

It was around the time that Chou had her kids, she states, that she realized the importance of making a brand name that was both environmentally sustainable and inclusive.

“I began constructing Everybody & & Everyone from the ground-up, very first by getting the very best group in location then by discovering the ideal vendors, makers and partners who were currently making strides in the sustainability space,” Chou said in a statement. “I desired this brand to be for every female, so body positivity, inclusivity and sustainability were going to be the foundation of everything we did. We then constructed the brands sustainable & & technical pillars, which consist of activation, recycled, coloring & & printing, naturals done better, bio-based fibers and end usage to guarantee our items would minimize unfavorable impacts. We are sustainable down to the labels stitched into each garment.”

Everybody & & Everyone has also partnered with the company One Tree Planted to plant a tree for each purchase that’s made with the company. In addition, the company has determined its carbon footprint from all of its pre-launch activities and has actually purchased and retired offsets to stabilize its emissions, Chou states.

Some clothes are also made with materials that have recycled silver in them– so that the clothing can be worn several times without smelling or the need for a wash.

“It was six years ago I started discovering about sustainability and 5 years ago that I stated that I required to have a sustainable brand name,” states Chou.

Everyone & & Everyone uses the lessons that Chou has actually found out about sustainability to a brand-new style brand that she hopes can serve as a design for how to weave sustainability into every element of the industry.

The new brand, which sells women’s clothing for every single size from 00 to 24 and at prices varying from $18 to $288 (most fall in the $50 to $150 variety, given a fast scroll through the company’s brand-new website) partners with business like Naadam and Ecoalf for sustainable cashmere and recycled fabrics made from plastic.

Veronica Chou’s family has made its fortune at the leading edge of the fast fashion industry through investments in business like Michael Kors and Tommy Hilfiger. But now, the heiress toan approximated $2.1 billion fortune is releasing her own company, Everybody & Everyone, to show that the style industry can be both environmentally sustainable and lucrative. There’s no argument about the unfavorable effects

well. About 20 %of commercial water pollution internationally can be traced to the dyeing and treatment of textiles– and microplastics from polyester, acrylic and nylon are polluting the world’s oceans. On the other hand, the rise of quick style has actually encouraged customers to speed up waste. Approximately one garbage truck full of clothes is landfilled all over the world every 2nd, according to a 2017 report from the Ellen MacArthur Foundation. That indicates consumers are discarding around $400 billion worth of important items every year as low costs and more “seasons” develop an impression of disposability.

“For our brand name, recycled is a huge story for us,” says Chou. “Our t-shirts, our socks, our packaging, our mailers, our labels, our stickers are all made from recycled materials that can be recycled once again.”

Since that revelation, Chou dove into the world of sustainable production head-first. Through her household’s investment vehicles she has dealt with business like Modern Meadow, which utilizes bio-engineering to make leather items in a lab. Chou has actually also led investments in Thousand Fell, a soon-to-launch producer of completely recyclable shoes; Dirty Labs, which is developing more sustainable laundry cleansing items; and Carbon Engineering, which is developing a direct air capture innovation for co2.

For Chou, an understanding of the environmental toll that the family service was handling the planet started 6 years ago– a couple of years before Iconix Brand Group got the China subsidiary she had actually co-founded with her dad in a transaction apparently worth $56 million.

of the fashion market on the environment. The textiles market primarily utilizes non-renewable

resources– on the order of 98 million heaps per year. That includes the oil to make artificial fibers, fertilizers to grow cotton and harmful chemicals to dye, treat and produce the textiles used to make clothes. The greenhouse gas footprint from textiles production was roughly 1.2 billion lots of CO2 equivalent in 2015– more than all global flights and maritime deliveries combined(and a lot of those maritime shipments and international flights were hauling clothing). The list of catastrophes that can be credited to the clothing market encompasses contamination, as

Veronica Chou’s family has made its fortune at the forefront of the fast fashion business through investments in companies financial investments Michael Kors and Tommy Hilfiger. And her dad, Silas Chou, made millions as an investor in Michael Kors and Tommy Hilfiger. As an executive at Iconix Brand Group China, Veronica Chou played a function in the velocity of the industry– bringing American brands to Chinese consumers. Since that revelation, Chou dove into the world of sustainable production head-first.”For our brand name, recycled is a huge story for us,” says Chou.

Meanwhile, previous Uber executive Dmitry Shevelenko unveiled Tortoise, an autonomous repositioning software application for micromobility operators. The concept is to assist make it easier for these business to more tactically release their respective vehicles and reposition them when required.

Today, we’re taking a look at factories in China, scooters in San Francisco and touchscreens in automobiles, amongst other things.

Welcome to micromobbin’– a weekly dive into the magnificent however small chaotic world of micromobility.

Parts of the newsletter will be released as a post on the primary site after it has actually been emailed to subscribers (that’s what you’re reading now). To get everything, you have to register. And it’s totally free. To subscribe, go to our newsletters page and click on The Station.

Let’s close this section with the required financing round. Wheels, a pedal-less electric bike-share start-up, raised a $50 million round led by DBL Partners. That brought its overall funding to $87 million.

This also occurs to be a place where Megan Rose Dickey reigns. Follow her @meganrosedickey. Uber, Lime and Spin each released 500 electrical scooters in San Francisco as part of the city’s permitting program. This means locals in SF can now select from Uber-owned JUMP, Lime, Spin or Scoot scooters. Regrettably for Skip, the business did not get a license to continue operating in the city, which implies layoffs at the regional level are afoot, Skip CEO Sanjay Dastoor said earlier this week.

This is the current example of Uber’s plan to become an incredibly movement app that goes well beyond its own network of ride-hailing vehicles.

Oh, however wait, TC reporter Romain Dillet reminded us that micromobbin’takes place beyond the U.S. too. Uber also revealed this past week that it has actually integrated its app with French start-up Cityscoot, which has a fleet of free-floating moped-style scooters.

The Station is back for another week of news and analysis on all the methods people and products move from Point A to Point B– today and in the future. As constantly, I’m your host Kirsten Korosec, senior reporter at TechCrunch.

Please connect anytime with ideas and feedback. Tell us what you like and don’t enjoy a lot. Email me at kirsten.korosec@techcrunch.com!.?.! to share viewpoints, thoughts or tips or send out a direct message to @kirstenkorosec. Micromobbin’

— Megan Rose Dickey

Snapshot: Touchscreen tech

The genuine chance for Sentons will be with self-governing cars, a product that will manage its travelers more leisure time.

We’ve seen a lot of various approaches when it pertains to engaging with linked vehicle services: head-up display screens on the windshield, little screens set down on the control panel, interactive voice and, naturally, connections and mounts for smartphones.

CEO Jess Lee states the next versions are going to be the type of materials that are utilized to make cars and truck control panels and other interior surfaces you find inside the automobile, including leather, thicker plastic and other materials. The company is currently engaging with automotive companies, Lee informed TechCrunch.

I can see a great deal of possibilities for this in the human-driven automobiles of today. We’ve currently seen how Tesla has actually changed how we think of infotainment systems in cars and trucks. And then there’s electrical vehicle startup Byton, which prepares to bring a lorry to market with a touchscreen that extends along the whole control panel.

But how about if your entire automobile becomes the touchscreen? A startup called Sentons is working on innovation that might make that happen. The business utilizes a technique including processors and AI that check out and release ultrasound to spot physical motion on a surface area, such as touch, force or gestures, and users can develop “virtual controls” on the fly that work on these surfaces.

— Ingrid Lunden

Made in China

Earlier today, Tesla was given the OKAY to start producing lorries at its $2 billion factory in Shanghai. Tesla was included to the Ministry of Industry and Information Technology’s list of approved automobile makers.

This all sounds fantastic, however there have actually been challenges, and the consistent requirement for capital is one of them. Byton has postponed the launch of the production version of the M-Byte by two quarters. It’s now looking like industrial production will start by the end of the second quarter of 2020.

In other China factory news, we hear that electric automobile start-up Byton prepares to host a splashy opening event in early November for its brand-new plant. The occasion will consist of lots of Chinese officials, company executives and perhaps a preview of a near-final production version of its M-Byte vehicle.

Now we’ll enjoy and wait to see if production starts this month. Anticipate the subject of China and this factory to come up during Tesla’s revenues call with experts October 23.

The plant will start trial production in late 2019.

Byton’s factory in Nanjing covers some 800,000 square meters (8.6 million square feet) funded with a total financial investment of more than $1.5 billion. Over the summertime, the walls and roofing system went up, devices was set up and commissioning started in 5 major workshops: stamping, welding, paint, assembly and battery.

Here are a number of intriguing tidbits for those manufacturing geeks out there:

We hear a lot. However we’re not self-centered. Let’s share. A little bird is where we pass along expert tips and what we’re hearing or finding from trustworthy, educated sources in the market. This isn’t a location for unproven gossip.

To get a “little bird” and the rest of the newsletter, please subscribe. Simply go to our newsletters page and click on The Station.

- The stamping shop finishes one panel every 3 seconds typically. Byton declares it will be one of the fastest stamping production lines in China.

- The welding store integrates 335 welding robotics provided by KUKA and improves the automation rate to 99%, according to Byton.

- The paint store is geared up with a “3 Coating 2 Baking” system and thin movie pre-treatment as well as the transverse “Eco-Incure” oven technology.

- The battery shop will produce and assemble battery packs, developed independently by Byton. Battery maker CATL supplies the battery cells and modules and aluminum maker Constellium provides the aluminum battery tray.

A little bird

What does systems engineering in AVs suggest?

We asked the concern, what do we need to show to ourselves and show in order to be on a public road securely? It’s the very same question that we’re going to have to respond to for the product also, which is, what do we need to show to guarantee that we’re safe to operate without a human in the cab?

It’s one of the substantial unproven hypotheses. Anybody in this space that doesn’t consider that to be a huge technical obstacles is disregarding a important and actually thorny concern.

The total interview was consisted of in the emailed newsletter. Another factor to subscribe to this complimentary newsletter. Here’s one quote from the interview with Aikin:

The business also released a wickedly long safety report (it’s midway down that landing page in the link provided).

Who will own the future of transport?

Our mobility coverage reaches Extra Crunch. Have a look at my newest short article on who will own the future of transport based on insights from < a class="crunchbase-link"href="https://crunchbase.com/organization/zoox"target="_ blank"data-type="company"data-entity= “zoox”> Zoox CEO Aicha Evans and former Michigan Gov. Jennifer Granholm. The concept here is to check out some of the subtleties of this loaded concern.

Bonus Crunch requires a paid membership and you can register here.

Oh, however wait, TC press reporter Romain Dillet reminded us that micromobbin’takes place exterior of the U.S. too. CEO Jess Lee says the next models are going to be the kinds of materials that are utilized to make cars and truck control panels and other interior surface areas you discover inside the car, consisting of leather, thicker plastic and other products. Earlier this week, Tesla was given the OKAY to start producing vehicles at its $2 billion factory in Shanghai. We hear a lot. I recently spoke to Randol Aikin, the head of systems engineering at self-driving trucks start-up Ike Robotics, about the company’s approach, which is based on an approach established at MIT called Systems Theoretic Process Analysis.

As the fashion industry has actually broadened, so has the wealth of the Chou household. South Ocean Knitters, the knitwear manufacturer started by Chou’s grandpa, was accountable for one of the first foreign financial investments into mainland China in 1974. It is now among the largest suppliers of knitwear in the world, and, together with the Hong Kong manufacturer Li & & Fung, is behind the Cobalt Fashion Holding corporation.

“For our brand, recycled is a huge story for us,” says Chou. “Our tee shirts, our socks, our product packaging, our mailers, our labels, our sticker labels are all made from recycled products that can be recycled once again.”

Everyone & & Everyone has actually likewise partnered with the organization One Tree Planted to plant a tree for each purchase that’s made with the business. In addition, the company has computed its carbon footprint from all of its pre-launch activities and has bought and retired offsets to balance its emissions, Chou states.

Image thanks to World Resources Institute

“It was 6 years ago I began discovering sustainability and 5 years ago that I said that I required to have a sustainable brand name,” states Chou.

Everyone & & Everyone applies the lessons that Chou has found out about sustainability to a brand-new fashion brand that she hopes can serve as a model for how to weave sustainability into every aspect of the market.

Some clothes are likewise made with fabrics that have actually recycled silver in them– so that the clothes can be worn multiple times without smelling or the requirement for a wash.

For Chou, an understanding of the ecological toll that the household organisation was taking on the planet began six years ago– a few years before Iconix Brand Group obtained the China subsidiary she had actually co-founded with her daddy in a deal reportedly worth $56 million.

Veronica Chou’s household has made its fortune at the forefront of the fast fashion industry through investments in companies like Michael Kors and Tommy Hilfiger. Now, the heiress toan approximated $2.1 billion fortune is releasing her own company, Everybody & Everyone, to show that the fashion industry can be both ecologically sustainable and lucrative. There’s no argument about the unfavorable impacts

Digital printing is used in place of screens to avoid loads of water waste, the company stated, and several of the company’s materials are not dyed at all. instead, the business depends on an upcycling process by separating recycled fibers mechanically by color.

of the fashion business on the environment. The fabrics industry primarily uses non-renewable

resources– on the order of 98 million loads each year. That consists of the oil to make artificial fibers, fertilizers to grow cotton and hazardous chemicals to color, treat and produce the textiles utilized to make clothing. The greenhouse gas footprint from fabrics production was roughly 1.2 billion lots of CO2 equivalent in 2015– more than all international flights and maritime deliveries integrated(and a great deal of those maritime shipments and worldwide flights were carrying clothing). The litany of disasters that can be credited to the clothes market reaches pollution, as

Since that discovery, Chou dove into the world of sustainable manufacturing head-first. Through her household’s investment cars she has actually dealt with companies like Modern Meadow, which uses bio-engineering to make leather goods in a lab. Chou has actually likewise led financial investments in Thousand Fell, a soon-to-launch producer of totally recyclable shoes; Dirty Labs, which is establishing more sustainable laundry cleansing products; and Carbon Engineering, which is establishing a direct air capture innovation for co2.

It was around the time that Chou had her children, she states, that she recognized the value of making a brand that was both environmentally sustainable and inclusive.

The business’s attention to its environmental impact likewise encompasses its supply chain. “Most of our materials are knit close to where our garments are made. That is absolutely minimizing our carbon footprint,” states Chou. “I put an emphasis on having factories in America … our denim is produced in America and in the future we’re looking at tee shirts and athletics to be manufactured in America.”

“I started building Everybody & & Everyone from the ground-up, very first by getting the best team in location then by discovering the best vendors, partners and producers who were currently making strides in the sustainability area,” Chou stated in a declaration. “I wanted this brand name to be for each woman, so body sustainability, positivity and inclusivity were going to be the foundation of whatever we did. We then built the brand names sustainable & & technical pillars, which include activation, recycled, dyeing & & printing, naturals done better, bio-based fibers and end usage to ensure our products would minimize negative effects. We are sustainable down to the labels sewn into each garment.”

And her daddy, Silas Chou, made millions as an investor in Michael Kors and Tommy Hilfiger. As an executive at Iconix Brand Group China, Veronica Chou played a function in the acceleration of the market– bringing American brands to Chinese consumers. Chou also acted as the co-founder of the Beijing-based private equity fund China Consumer Capital and as a director of Karl Lagerfeld Greater China.

The new brand, which sells women’s clothes for each size from 00 to 24 and at costs varying from $18 to $288 (most fall in the $50 to $150 range, offered a fast scroll through the business’s brand-new website) partners with business like Naadam and Ecoalf for sustainable cashmere and recycled materials made from plastic.

well. About 20 %of industrial water contamination globally can be traced to the dyeing and treatment of textiles– and microplastics from polyester, acrylic and nylon are polluting the world’s oceans. Meanwhile, the increase of fast style has motivated consumers to accelerate waste. Approximately one garbage truck complete of clothing is landfilled around the world every 2nd, according to a 2017 report from the Ellen MacArthur Foundation. That implies consumers are getting rid of around $400 billion worth of important goods every year as low rates and more “seasons” develop an illusion of disposability.

Veronica Chou’s family has made its fortune at the forefront of the leading edge fashion business through investments in companies like Michael Kors and Tommy Hilfiger. And her daddy, Silas Chou, made millions as a financier in Michael Kors and Tommy Hilfiger. As an executive at Iconix Brand Group China, Veronica Chou played a function in the acceleration of the industry– bringing American brands to Chinese consumers. Because that revelation, Chou dove into the world of sustainable production head-first.”For our brand, recycled is a huge story for us,” states Chou.

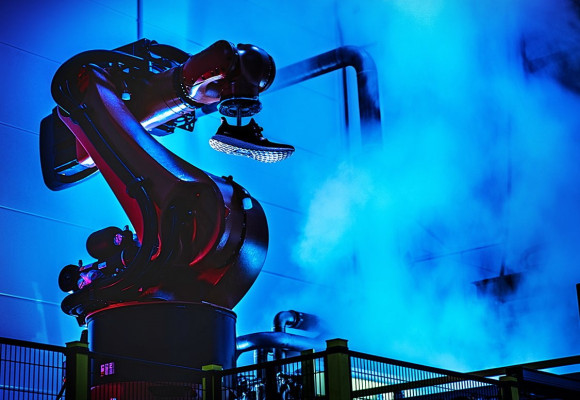

The business sugar-coated the news with a pledge to repurpose the innovation used at its existing human-powered factories in Asia.” We really much regret that our cooperation in Ansbach and Atlanta has come to an end, “Shankland said. “Whilst we comprehend adidas’reasons for terminating Speedfactory production at Oechsler, we regret this decision,” stated the company’s CEO, Claudius Kozlik, in the press release. The release states that Adidas will”utilize its Speedfactory technologies to produce athletic footwear at two of its suppliers in Asia “starting next year.

The business sugar-coated the news with a guarantee to repurpose the innovation used at its existing human-powered factories in Asia. “Whilst we comprehend adidas’reasons for discontinuing Speedfactory production at Oechsler, we regret this choice,” said the company’s CEO, Claudius Kozlik, in the press release. The release states that Adidas will”use its Speedfactory technologies to produce athletic footwear at 2 of its suppliers in Asia “starting next year.