After 6 years as head of DuPont, Ellen Kullman joins the fast-growing 3D printing company

You’ve been on a number of boards. What attracted you to Carbon, specifically?

This interview has actually been modified for length and clearness.

When was it clear that your time [at DuPont] had type of run its course?

For six years, Kullman headed up DuPont, the conclusion of a nearly 30-year career at the chemical giant. After 6 years at the helm of the company, co-founder Joe DeSimone stepped aside in November and ended up being Executive Chairman of the Board. Over the past couple of years, the business has formed partnerships with Adidas, Ford, Ridell and a number of other manufacturers. It was a proxy contest, and we won the proxy contest, however the activists made it clear that he was going to keep coming after the company. Being a mechanical engineer and running a company like DuPont with polymers, I comprehended injection molding pretty well.

After six years at the helm of the company, co-founder Joe DeSimone stepped aside in November and ended up being Executive Chairman of the Board. His background as a chemist assisted birth the start-up, while Kullman’s experience leading a Fortune 500 plainly suggest a company wanting to take the next steps.

Being a mechanical engineer and running a business like DuPont with polymers, I understood injection molding pretty well. I comprehended how we at DuPont were helping consumers try to enhance what they were doing with pure material science. What struck me when I came out here is that digitization, technology, had impacted everything we do. Supply chain, our ERP, our HR systems. Everything around the manufacturing have been touched other than, producing itself. Yeah, we might have smarter DCS systems that are running the lines and things like that, however injection molding hasn’t changed for hundreds … the fundamentals. And this has a chance to fundamentally change it at a scale and a cost that was pertinent. My huge thing at DuPont is we could do remarkable things with creating new materials, brand-new environments for those products.

As somebody who recognizes with manufacturing and injection molding, you’ve definitely understood about 3D printing/additive manufacturing for a very long time now. To your mind, what is Carbon’s differentiator?

It was a proxy contest, and we won the proxy contest, however the activists made it clear that he was going to keep following the company. I truly was the lightning rod? It became individual to him that DuPont beat him, right? The only thing that was going to get that calmed down, I chose, was me leaving. I ‘d existed 27 years. I ‘d run seven years as the CEO. I had a terrific track record on gross, and on TSR, versus the S&P and things like that.

Last month, Carbon announced its very first brand-new CEO in the business’s history. With $260 million worth of investments and a $2.5 billion, it’s a huge task. Carbon’s 500-person headcount is little potatoes compared to Ellen Kullman’s last gig.

As several considerable funding rounds can testify, there’s plainly enormous interest in Carbon’s capacity. Over the past few years, the business has formed collaborations with Adidas, Ford, Ridell and a variety of other producers. As its newly-minted CEO, Kullman’s task will be following through on those deals and proving the business’s capacity as a crucial gamer in the future of production.

For 6 years, Kullman headed up DuPont, the conclusion of a nearly 30-year career at the chemical giant. After leaving the role in 2016, she signed up with a variety of various boards, consisting of Goldman Sachs and Dell. It was, nevertheless, a three-year-old Bay Area-based 3D printing business that ultimately drew her interest.

It was just the right time to exit. Essentially the decision came up in the middle of ’15 and you know, I stepped down in late October, I believe it was. That was pretty quick for a transition therefore that’s why I took a couple of years to find out what I wished to do. Really the very first thing I took on was agreed to begin Carbon’s board about four months after I left DuPont.

Zetwerk has also made it possible for producers in India to discover and discover customers overseas. Acharya stated Zetwerk mostly competes with domain job specialists in the offline work., said, “the usage of innovation in task preparation, audits, procurement, and supply chain transparency is the core offering of Zetwerk which is entirely initial.

Unlike the more typical e-commerce firms we come across every day, Zetwerk sells products such as parts of a crane, doors, chassis of various makers and ladders. Presently, Zetwerk works with more than 100 business and 1,500 small and medium-sized companies. Zetwerk has also enabled manufacturers in India to discover and discover customers overseas. Acharya stated Zetwerk mostly competes with domain project specialists in the offline work., said, “the usage of technology in task preparation, audits, supply, and procurement chain transparency is the core offering of Zetwerk which is totally initial.

Another, the still-private business is Inscripta, helmed by a former TenX Genomics executive, the Boulder, Colo.-based start-up is commercializing a device that can let scientists design and manufacture little quantities of brand-new organisms. If TenX Genomics is providing scientists and services a much better way to read and understand the genome, then Inscripta is giving those exact same users a brand-new way to compose their own genetic code and make their own organisms.

Entrepreneurs and investors are releasing hundreds of countless dollars to produce the tools that scientists, scientists and industry will use to re-engineer the foundation of life to perform different functions in production, medication and agriculture.

That wasn’t the only barrier that Inscripta felt that it needed to breakdown. The company likewise developed a proprietary biochemistry for gene modifying, hoping to prevent needing to pay charges to among the 2 labs that were engaged in a pitched legal fight over who owned the CRISPR innovation (the Broad Institute and the University of California both had claims to the technology).

In these subsiding days of the second years of the twenty-first century, investors and technologists are starting to lay the structures for brand-new, truly transformational innovations that have the possible to reshape whole industries and reword the guidelines of human understanding.

It’s a technology that financiers are falling over themselves to fund. The company, which closed on $105 million in financing earlier in the year (through several tranches which started in late 2018), has just raised another $125 million on the heels of releasing its very first commercial item. Financiers in the round consist of new and previous investors like: Paladin Capital Group, JS Capital Management, Oak HC/FT and Venrock.”Biology has endless capacity to positively change this world, “states Kevin Ness, the primary executive of Inscripta.”It’s one of the most essential brand-new technology forces that will be a major gamer in the worldwide economy.”

It may sound lofty, but new achievements from businesses and research organizations in locations like device learning, quantum computing, and genetic modification imply that the futures thought of in sci-fi are simply becoming science.

Earlier this year the business announced that it was taking orders for its first bio-manufacturing item and the new capital is designed to spend for expanding its manufacturing capabilities.

Among these business, 10X Genomics, which provides users software and hardware to determine the performance of various genetic code, has already shown how financially rewarding this early market can be. The company, which had its going public earlier this year is now worth $6 billion.

Ness sees Inscripta as breaking down among the biggest barriers to the commercialization of genetic modification, which is access to the technology.

While genome centers and biology foundries can make enormous amounts of brand-new biological material for commercial usages, it’s too pricey and centralized for a lot of scientists. “We can put the biofoundry abilities into a box that can be pushed to an international scientist,” states Ness.

And amongst the technologies that might possibly have the biggest effect en route we live, nothing looms larger than genetic modification.

, helmed by a former TenX Genomics executive, the Boulder, Colo.-based start-up is advertising a device that can let scientists style and produce little quantities of new organisms. It’s an innovation that investors are falling over themselves to finance. The company, which closed on $105 million in financing previously in the year (through several tranches which started in late 2018), has just raised another $125 million on the heels of introducing its very first industrial item. Financiers in the round include new and previous financiers like: Paladin Capital Group, JS Capital Management, Oak HC/FT and Venrock.

Spinning syntax invalid.

The next huge thing in robotics and automation just may be building. Innovation has actually already transformed production and logistics, and now a variety of well-funded start-ups are wanting to do the exact same to the building industry. This March at TC Sessions: Robotics+AI, we’ll be bringing together a trio of business that have the market and financiers buzzing. Noah Campbell-Ready is the founder and CEO of Built Robotics, a start-up that has actually established a sturdy self-governing bulldozer. The system has actually already been piloted for 7,500 hours, with a best security record. The company raised a $33 million Series B in September, bringing its overall up to $48 million.

Tessa Lau is the CEO and founder of Dusty Robotics, a Bay Area-based start-up that has actually established a robot created to assist automate structure layouts at building and construction sites. The robotic is capable of bringing strategies to life with severe accuracy. Dirty raised a $5 million seed round last month.

The companies will be joining us on phase at UC Berkeley on March 3 for TC Sessions: Robotics+AI to go over how robotics and automation will assist change building and construction sites of the future.

Toggle CEO Daniel Blank will be completing the pan. A newcomer, the Brooklyn-based business raised a $3 million seed round in October for robots the fabricate and put together rebar.

Technology has actually already changed manufacturing and logistics, and now a number of well-funded start-ups are looking to do the very same to the building industry., we’ll be bringing together a trio of companies that have the market and financiers buzzing. The robotic is capable of bringing plans to life with severe accuracy.

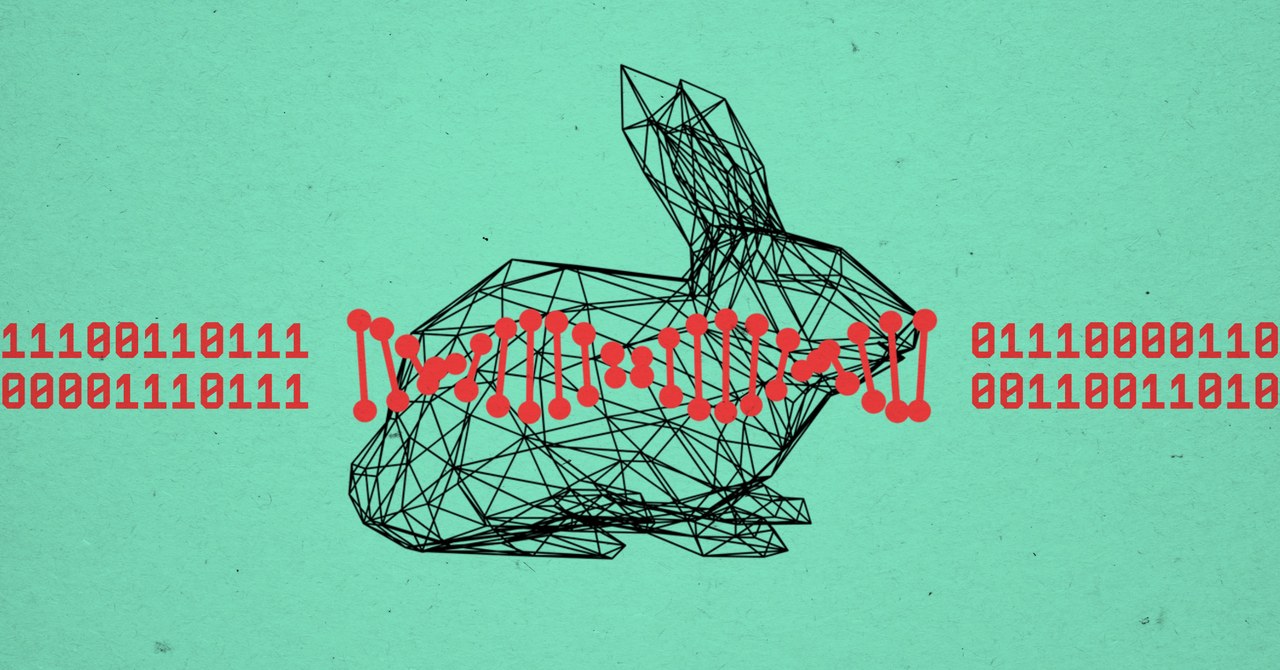

The bunny became a training school for a generation of computer graphics designers. They discovered how to layer textures and render fur over its leporine curves. It was smashed and fractured and melted in service of advancing their animation skills. It ended up being so iconic that to this day, almost anyone finding out to use a 3D printer begins by making a plastic version of the exact same bunny.

In a method, Erlich’s bunny is the supreme inside joke. “Plus, you know, you pull rabbits out of the hat,” he states. A computational biologist-slash- white-hat hacker, Erlich gained notoriety in the mid-2000s for utilizing a well-placed cell phone to get into a significant Israeli bank. A couple of years later on, he unmasked the identities of individuals noted in a confidential hereditary database, utilizing only a web connection. Then, in 2015, he showed that such databases have actually grown so huge, it’s now possible to discover over half the United States population, even people who’ve never taken a DNA test. He first hatched the idea for DNA-infused objects with his brother in-law, a graphic designer. They were speaking about how to make pictures– genuine ones, the kind you put in frames and albums– hold up gradually. It made him think: Maybe it would be possible to transform a jpeg file into DNA and spray it on the photo itself, a finishing step to provide it digital replicability.

But DNA is a vulnerable particle. Heats, strong pH swings, and UV light all cause it to deteriorate, degrading the details it encodes. Protecting its chemical structure is crucial to any DNA data storage dreams.

Erlich emailed Grass, the person who ‘d originated a technique to trap DNA molecules inside a tiny protective glass shell. In 2013, he had figured out how to produce silica particles with a favorable electrical charge, making them adhere to negatively charged DNA. They ‘d form a thin film that might protect the molecule from a number of dangers.

Using that technology, the pair developed a procedure for producing materials with their own DNA memory, just like the cells in your own body. It involves very first transforming the digital blueprint of a things into a hereditary sequence, producing the corresponding molecules of DNA, encasing them in silica, embedding the beads in melted plastic, spinning that plastic into filaments, filling those filaments into a 3D printer and then printing the things. Easy! They explain the work in today

‘s issue of Nature Biotechnology. Simply as it’s in theory possible to take a couple of cells from your body and make another copy of you as a clone, you can snip a little piece off Erlich’s bunny and utilize it to make others. The one he brings around, in reality, is a third-generation clone. The information file Grass’s team used to 3D-print it was obtained from a tiny piece of ear from a bunny that had actually originated from a small piece of an ear of the first bunny they made. They liquified away the plastic and glass from the ear piece, converted the remaining DNA back into a digital file, and published the file to a 3D printer. All together, the scientists made five generations of bunnies without any information loss between production cycles. The bunnies, and the digital files that explained them, remained identical over lots of months.

“This is an extremely initial venture into among the more promising applications of DNA data storage: common storage,” states Sriram Kosuri, a biochemist at UCLA who was not associated with the work. With ubiquitous storage, all daily items might be tagged with beneficial info, such as where they were made, their ingredients or structure, user’s manual, security cautions, and suggestions for how finest to recycle or get rid of the product. “What’s cool about this work is they reveal that it is doable today, and it appears pretty dependable,” says Kosuri.

In 2013, he had figured out how to create silica particles with a favorable electrical charge, making them stick to negatively charged DNA. Using that technology, the set designed a procedure for producing materials with their own DNA memory, just like the cells in your own body. It includes very first converting the digital blueprint of a things into a hereditary sequence, producing the corresponding particles of DNA, enclosing them in silica, embedding the beads in melted plastic, spinning that plastic into filaments, loading those filaments into a 3D printer and then printing the object. They liquified away the plastic and glass from the ear fragment, transformed the remaining DNA back into a digital file, and uploaded the file to a 3D printer.”This is a really initial venture into one of the more promising applications of DNA data storage: common storage,” says Sriram Kosuri, a biochemist at UCLA who was not involved in the work.

At the time, it was one of several business– including Memphis Meats, Future Meat Technologies, Aleph Farms, HigherSteaks and many, lots of pursuing technologies– to bring cultured beef to market. That’s not the only method the business is setting itself apart from its peers in the market. To pursue its brand-new path, the company has actually raised $7 million from a variety of angel and institutional investors and a $3 million grant from the European Commission.

At the time, it was one of a number of companies– including Memphis Meats, Future Meat Technologies, Aleph Farms, HigherSteaks and lots of, numerous pursuing innovations– to bring cultured beef to market. That’s not the only way the company is setting itself apart from its peers in the market. To pursue its new course, the business has actually raised $7 million from a slew of angel and institutional investors and a $3 million grant from the European Commission.

LG Chem and GM have been working together considering that 2009. The relationship deepened as GM established and then launched the Chevy Bolt EV. The battery plant is anticipated to have a yearly capacity of more than 30 gigawatt hours with flexibility for expansion, according to GM. The area of the battery venture might develop goodwill in Lordstown, a town that suffered from sweeping lay offs after GM chose to stop producing the Chevrolet Cruze at its assembly plant there.

LG Chem and GM have actually been working together because 2009. The battery plant is expected to have a yearly capability of more than 30 gigawatt hours with flexibility for growth, according to GM. The location of the battery venture could develop goodwill in Lordstown, a town that suffered from sweeping lay offs after GM decided to stop producing the Chevrolet Cruze at its assembly plant there.

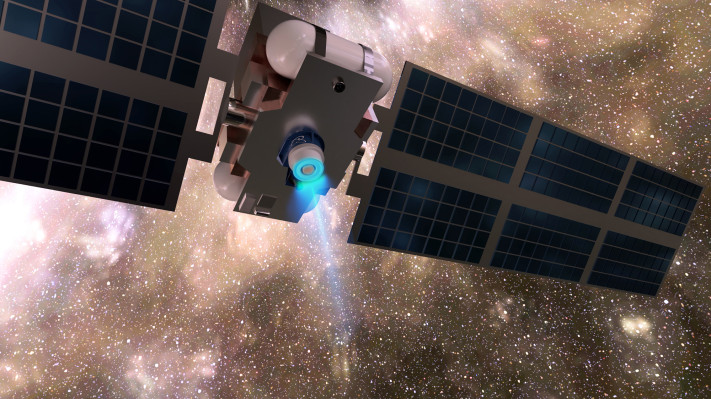

OrbitsEdge, founded earlier this year, has actually developed an exclusive piece of hardware called the “SatFrame” which is created to counter the stress of a space-based operating environment, making it fairly easy to take off-the-shelf Earth equipment like the HPE Edgeline system and get it working in area without requiring a huge amount of additional, custom-made work.

The partnership will make OrbitsEdge a hardware provider for HPE’s Edgeline Converged Edge Systems, and essentially it means that the space start-up will be managing whatever required to “solidify” the standard HPE micro-data center equipment for usage in external area. Hardening is a standard process for getting things ready to utilize in space, and essentially prepares equipment to withstand the increased radiation, severe temperature levels and other stressors that area contributes to the mix.

In terms of what this will possibly offer, the partnership will suggest it’s more possible than ever to set up a small data center in orbit to deal with at least a few of the processing of space-based data right near where it’s collected, instead of needing to shuttle it pull back to Earth. That process can be expensive, and tough to source in terms of even finding business and facilities to utilize. As with in-space production, doing things locally might conserve a lot of overhead and unlock heaps of potential down the line.

What kinds of companies might be able to operate in area? Well, data centers are one possible target you might not have actually believed of. Area supplies an intriguing environment for information center operations, including sophisticated analytics operations and even artificial intelligence, due in part to the excellent cooling conditions and reasonable access to renewable power supply (solar). But there are challenges, which is why a brand-new partnership in between Florida-based space startup OrbitsEdge and Hewlett Packard Enterprises (HPE) makes a great deal of sense.

“One way to increase the strength of space systems is to improve our country’s ability to build and release small satellites in great deals at low expenses,” said King in a statement, “Orbion is developing mass-production strategies to construct propulsion systems for commercial consumers. With this research study contract we are examining how or if our manufacturing processes must be modified to meet DOD requirements.”

Generally, it seems like that will boil down to seeing how Orbion’s propulsion technology can be used to DOD satellites when used in larger constellation type, to supply those satellites with the capability to move propulsively while in orbit, and to do so at a way that can scale cost-effectively. In a news release revealing the news, Orbion CEO Brad King says that volume is a method when it comes to strengthening U.S. systems in space agains potential foreign attack.

It’s true that in the past, the U.S. and other global powers with access to space have mainly concentrated on large, expensive, singular pieces of orbital hardware as their tactical assets. Shifting to the little satellite constellation technique presently being pursued by a variety of personal business absolutely has advantages in regards to redundancy and replaceability.

Orbion’s whole organisation proposal as a start-up is that its applying mass-production to in-space thrusters, which will bring down costs and make their innovation available to a much larger range of prospective customers than ever previously, and useful for application in small satellite design. The DOD might not have the very same budget-constraint problems as a cash-strapped satellite startup, but long-term cost savings that also comes with a tactical advantage is a tough bargain to skip.