Tesla introduces its tabless battery design on the road to 10 terawatt hours of production

connections into the active product through a shingled spiral. That brand-new style indicates simpler manufacturing, less parts and a much shorter electrical course length, which is how Tesla gets the thermal benefits it declares, according to Baglino.”For cylindricals to be able to get rid of the tabs dramatically streamlines winding and finishing and has a remarkable thermal and efficiency benefit,”stated Baglino. Musk agrees.”It’s really a huge pain in the ass to have tabs,”Musk stated during the event. By minimizing the distance the electron needs to take a trip

, the cell has less thermal concerns and a much shorter path length in a larger tabless cell, according to Musk, who

of trials but we’re extremely delighted where we ended up,”said Baglino.

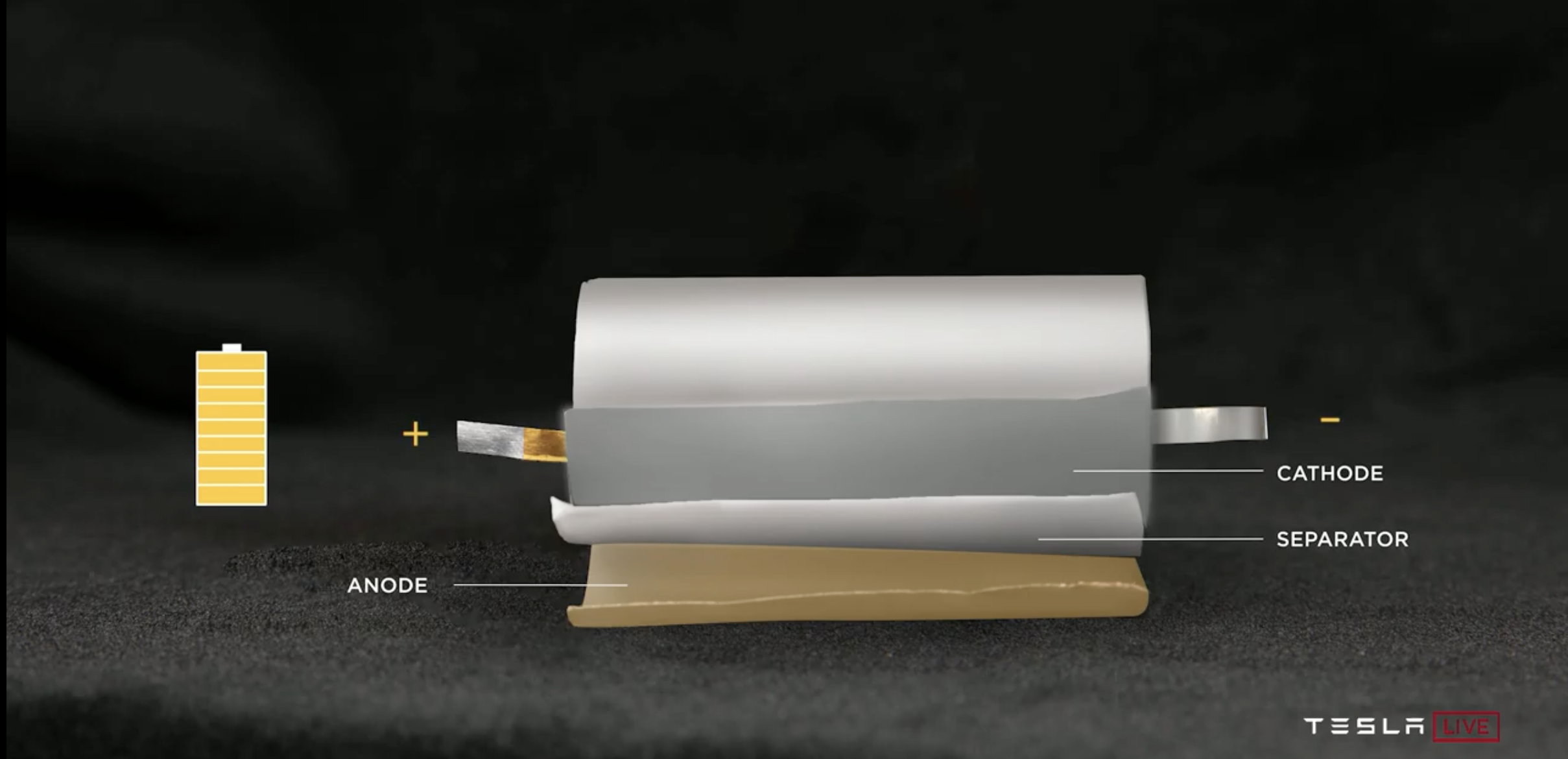

Today, throughout Tesla’s self-described Battery Day event, the business laid out a series of innovations that its CEO Elon Musk said will get it there. It should be kept in mind that this brand-new cell manufacturing system isn’t really working. Standard batteries are made of three components: the separator, the anode and the cathode. Standard battery structure, there are tabs that allow a cell’s energy to be moved to an external source. Image of a conventional lithium ion battery and its elements: the cathode, anode and separator.

“We’re beginning to increase production of these cells at our pilot 10 gigawatt manufacturing center just around the corner,” stated Drew Baglino, the SVP of powertrain and energy engineering at Tesla.

Lithium ions flow from the anode to the cathode through the separator to charge the battery and release. The procedure has actually been the same for batteries for decades and the changes have actually been mainly in the material science, and modifications to the size of the battery.

It should be kept in mind that this brand-new cell production system isn’t actually working. It’s “near working” at the pilot plant level, Musk added.

Traditional batteries are made from 3 components: the anode, the cathode and the separator. Fundamental battery structure, there are tabs that permit a cell’s energy to be moved to an external source. Large-format lithium-ion cells have a “foil-to-tab” weld to gather the foils inside a cell and join them to a tab.

As part of its announcements, the company has revealed the creation of a brand-new cell style, which the company stated has a new 80 millimeter length that will provide the cells 5 times the energy density, 6 times the power, and enable a 16% increase in range.

Today, throughout Tesla’s self-described Battery Day occasion, the company laid out a series of developments that its CEO Elon Musk stated will get it there. And all of it starts with a new building of the battery itself.

discussed that though the cell is larger, the power to weight ratio is better than a smaller sized cell with tabs.” This is rather hard to do, “stated Musk.”Nobody’s done it in the past. So … it actually took a remarkable quantity of effort within Tesla engineering to determine how do we

Image of a traditional lithium ion battery and its components: the separator, cathode and anode. Image Credit: TeslaThose changes in

make a fricking tabless cell and make it in fact work and link it to the top cap.” It’s the first of several steps that the company is taking to ramp up energy storage on its quest to move the world that much closer to renewable energy.”It took us a lot

For Tesla to reach the ambitious goal of 10 to 20 terawatt hours of battery production per year that the business has set, it will require to advance the battery and its production.

size to increase power and density include thermal problems, Baglino stated.”This was the difficulty that our team

set its sights on to conquer,”Baglino said.”We came up with this tabless architecture that removes the thermal problem from the equation that allows us to go to the absolute lowest cost kind aspect and the easiest manufacturing process. “Tesla took the existing foils and laser patterned them and allowed lots of